This project began as a cost-saving initiative when I discovered how expensive peristaltic pumps were on the market. Commercial options were either overpriced or lacked sufficient water flow, making them unsuitable for practical applications. Motivated by these limitations, I decided to create my own peristaltic pump for use in projects like a cold water dispenser and to improve the functionality of my Smart Pot system. Its food-safe design, which isolates water from the internal mechanism, made it the perfect choice.

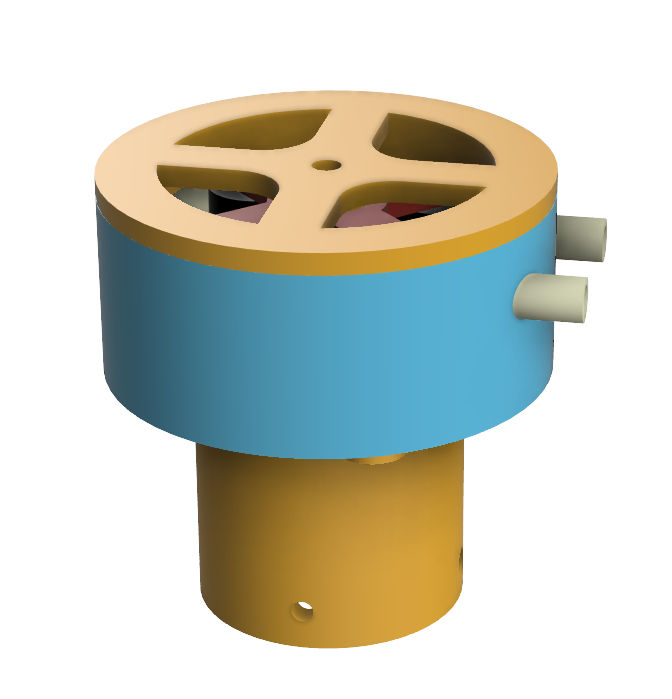

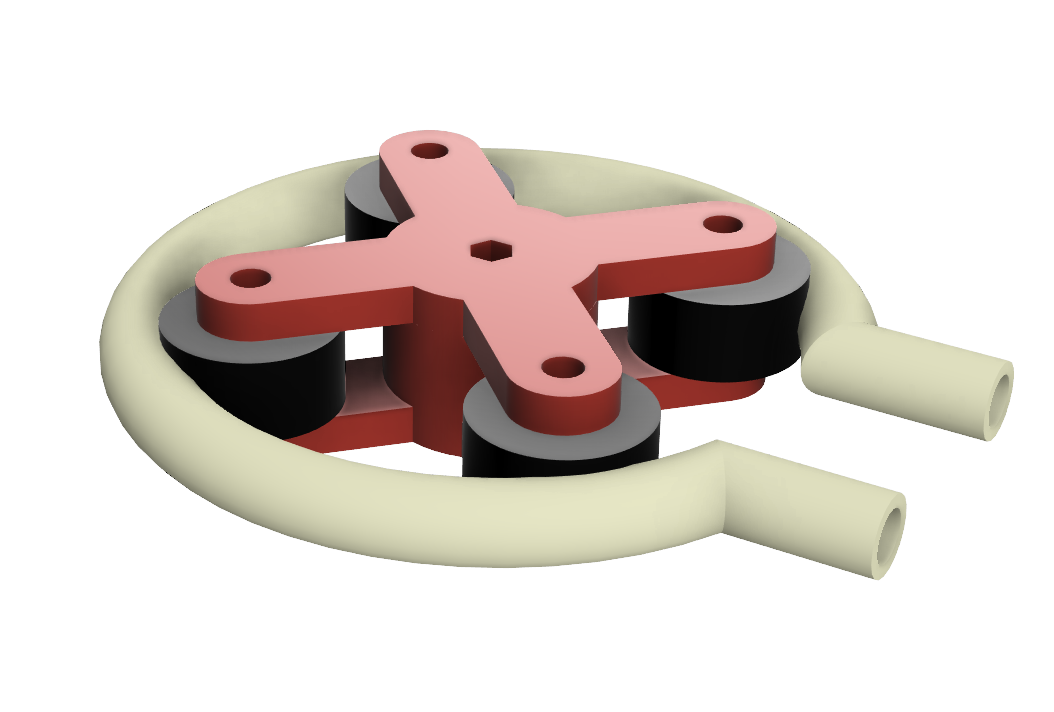

I designed the pump entirely in Fusion 360, focusing on functionality and efficiency. The main components include a 3D-printed housing and a motor with a gearbox salvaged from a robot vacuum cleaner. The design features a tube through which water flows, while rollers press against it to create the pumping motion. This construction ensures consistent water flow while maintaining hygiene and reliability.

The pump operates smoothly on six volts, with a manageable current draw. Lubrication is essential to prevent wear on the tubing, but the overall reliability and water flow rate exceeded expectations. Unlike conventional pumps, which often fail due to corrosion or clogging, this peristaltic design delivers better performance and durability, making it ideal for high-volume applications.

This peristaltic pump is highly versatile, supporting projects like cold water dispensers and advanced versions of my Smart Pot system. Its efficient design addresses common issues with traditional pumps, such as high start-up currents and frequent breakdowns, offering a dependable solution for food-safe and general-purpose fluid handling.